Custom Welded Metal Tube Frames

Ming Xiao Manufacturing Co., Ltd engaged in Metal Tube Frame custom manufacturing services more than 10 years, we have produced various types of stainless steel tube bending fittings from different, include welded tube and seamless pipe, Elliptical tube and rectangular tube.

We produce metal tube frames from materials of stainless steel tube, aluminum tube, carbon steel tube, brass & copper tube.It is usually used for handrails of carts, frames of Windows and chairs, kayak guardrail,handles of toolbox & building structures, industrial heating connecting tubes and other fields.

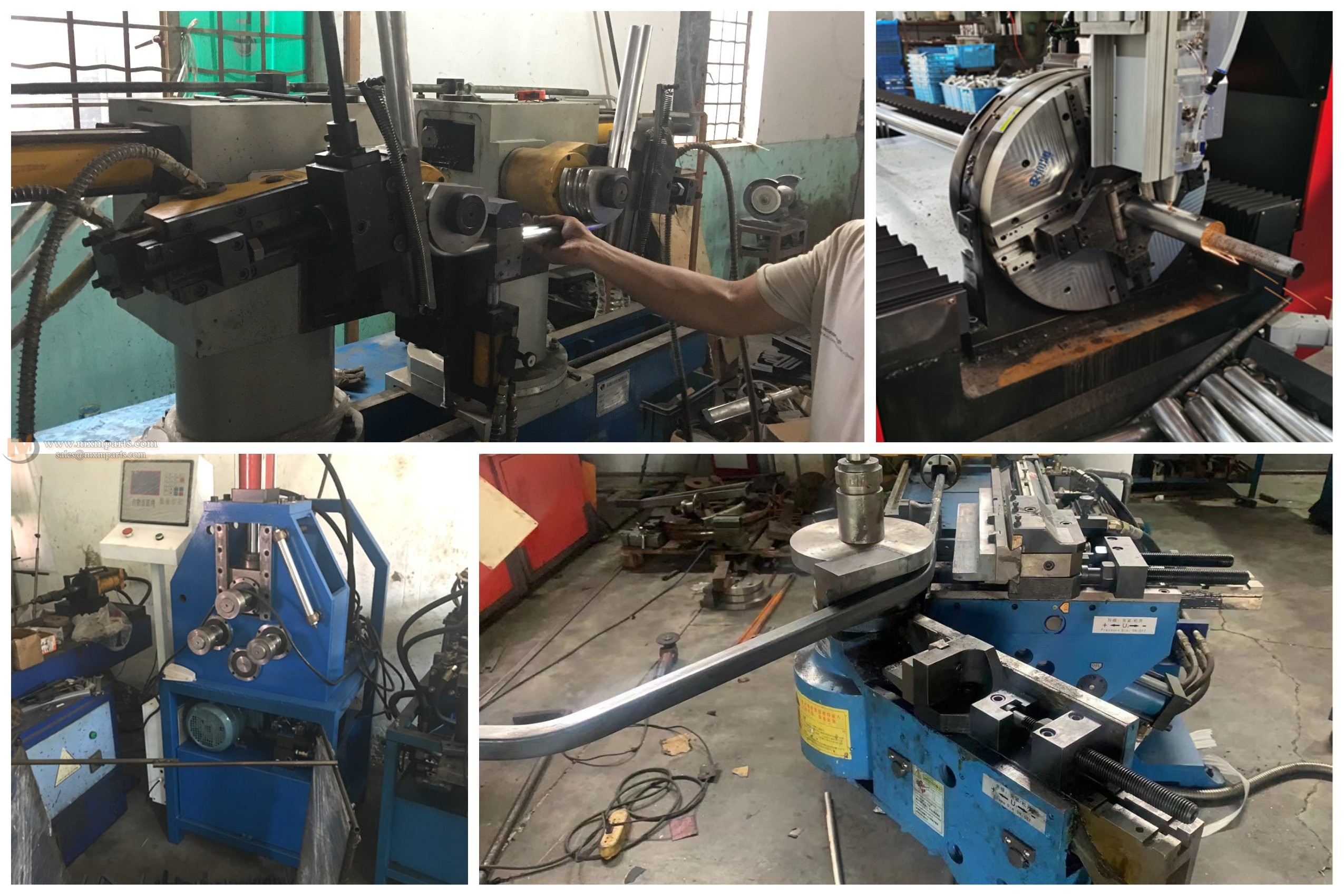

We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge machine, precision pipe cutting machine, welding machine, drilling Machine, etc.

Shapes Of Metal Tube Frames

We can produce metal tube frames in various shapes, such as straight tube, C-shaped tube, L-shaped tube, U-shaped tube, S-shaped tube, and complex three-dimensional tube components. And do finish of polishing,anodizing, painting, powder coating, electrophoresis and other surface treatment methods.

Are you finding a metal tube frame Supplier?

Ming Xiao Mfg undertake various metal tube frames customize service more than 10 years, We can provide convenient and fast service, prototyping is low, reliable quality, won the praise of domestic and foreign customers.

Welcome contact us to discuss your tube bending & fabricating components.

Shearing; crimping; laser cutting; bending; stamping; pressing; deep drawing; rolling; forming; fabricating; drilling; tapping; riveting; sopt welding; TIG; assembling

Materials for tube bending:

Seamless pipes & Welded pipes:

Carbon steel soft anneled

Stainless steel 201,304,316

Aluminum alloy of AL6061,AL5052,etc

Brass & Copper

Finish for tube bending:

Carbon Steel: Oiled, Heat treating, Carburization, Blackening (black oxide), Zinc plating, Chrome plating, Nickel plating, Powder coating, Painting, etc

Stainless Steel: Satin finish of Polishing & Milling, Brushed, Passivation, Chemical mirror polishing

Aluminum:Polishing, Brushed, Anodizing, Anodine, Powder coating, Painting, Electrophoresis, Vacuum coating, etc.

Lead time for custom new tube bending product is 30days.

Lead time for mass production:generally a order is 30-60days, if machining process is too complicated or quantity is very high,the lead time will longer.

We can provide COC (material certificate), Test Report, ROHS / SGS, plating report or coating reports also available !