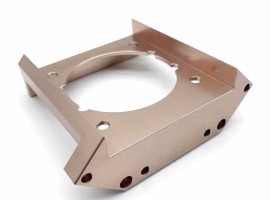

Custom Aluminum Stamping Parts

Ming Xiao Mfg specialize in sheet metal fabricating services more than 20 years,have been customed many kinds of sheet metal stamping parts & puched parts for different industries.

Providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc.

Have custom many kinds of aluminum stamping parts,such as aluminum stamping clamps, brackets,casings, holders,aluminum console covers,aluminum frames,aluminum punched plates,aluminum stamping Panel pressed-in hole parts by PEM studs, nuts, screws and pins.

We have more than 50 sets different tonnages conventional punches (stamping machines) from 5 tons – 320 tons, can produce max dimensions with 800mm*600mm sheet metal stamping parts, and the sheet parts thickness from 0.1mm – 8mm of carbon steel or brass, 3mm for stainless steel.

In addition to cold stamping, we also have high frequency heating machines that can provide hot forging services, and has welding machines, riveting machines, polishing machine,etc. multiple equipments can support us to produce more complex structure hardware products.

| Stamping die Specifications: | |

| Mould steel | DC53,SKD11,SKH9,Cr12,45#Steel, WC |

| Mould style | Single-station dies, Multi-station dies, Progresssive dies,Deep Drawing Dies |

| Finshing Operations | Forming, Bending,Deburring, Tapping |

| Accuracy | 0.005mm-0.05 according to thickness |

| Advantages: | High precision, fast stamping speed, saving labor and material costs |

| Tips: All products of the company support non-standard customization, a variety of material specifications are available. | |

We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume aluminum stamping parts.

We are professional China metal stamping parts manufacturers locate in Ningbo, we have produced many kinds of aluminum stamping parts for foreign customers with 15 years experiences, If you are interest in our custom metal stamping services, welcome send your design and requirements to us, we shall work a more competitive price for you.

The technics & capabilities for Metal stamping parts: Punching, cutting, bending / flexing / curving, pressing, forming,welding / bonding, riveting, grinding edge, lettering,Laser Cutting,Wire Cutting,Tapping, components Assembly.

Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc.

CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,).

stainless steel: 201,304(L),316(L),321,410,420,430

Aluminum alloy: 1060,2024, 3003,5052,6061,etc

All standard brass and copper: Pure Cu /E-Cu T1,T2,H73,H63,H62,H59,H58…

Finish treating: Anodizing,hard anodizing,electroplating of chrome/zinc/nickel plated, tinning,copperize,Colour spray-painting, blackening, hot-dip galvanizing, tephlon plating, etc.

Lead time for samples of Metal Stamping Parts in 15days.

Generally we use laser cutting or Wire cutting to cut the sheet instead of the punching die,this can save the mold cost once the design need change after samples,after samples approved, open the punching die.becase punching die is much expensive, and bending die is cheap, only make bending die for samples is ok, and it’s fast to make out samples.

Lead time for mass production: generally a order is 30-60days, if machining process is too complicated or quantity is very high,the lead time will longer.

We can provide COC (material certificate), Test Report, ROHS / SGS, plating report or coating reports also available !