Deep Drawn Parts from Ming Xiao Mfg

Ming Xiao Mfg manufacture Deep Drawn Parts at a competitive rate and using a wide variety of materials, grades, finishes, and served industries. We offer deep drawn parts to a vast array of customers ranging from small mechanical parts manufacturers to business conglomerates, executives, and established automakers. Our deep drawn parts are used for a range of applications ranging from small scale fixtures, precise electrical generators, and stronger automobiles as well. Our exquisite expertise has ensured us a wide authority in global markets, supplying service to customers anywhere in the world.

What is Deep Drawing?

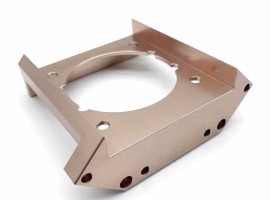

Deep drawn stamping is a part that uses a flat blank material to be processed into a cavity structure one or more times. As one of the main stamping processes, metal deep drawing is widely used in: round, barrel, spherical, conical, and other non- Regularly shaped thin-walled products, usually combined with other types of stamping processes, can produce custom metal parts with more complex structures.

Materials & Finishes

Our OEM/ODM manufactruring services come with a variety of state-of-the-art materials. They include – aluminum, brass, bronze, copper, stainless steel, carbon steel, steel alloy and titanium alloy.

We make sure that consumers tailor their pieces according to valuable finishes provided by us. With great pride, we give our customers guaranteed satisfactory finishes from sandblasting, zinc plating, passivating, etching and painting treatments according to their needs, giving uniquely suited looks to every order, allowing consumers to use our services for small prototypes up to mass-batch orders alike.

| Used Machines | Materials | Finishes | Application | Served Industries |

|---|---|---|---|---|

| Punch,Hydraulic Press | Aluminum,Carbon Steel,Stainless Steel, Brass, Copper, Kovar Steel | Zinc plating, Zince electroplating, Surface Finishing | Small fixtures, Heavy duty engines, Outlege pipes for oceanographic use | Engineering, Mechanical, Construction, Auto Manufacturing (includes Precious and Custom) |

Applications

Versatile use is one of our specialties as well. Whether the construction of factory parts, discrete furniture backs, or large house reconstruction parts, Ming Xiao proudly produces numerous end products that customers come looking for with great satisfaction from steel tubing to pipes, allowing customers to use our deep drawn metals and our surface treatments and present their products to various global markets.

Served Indutries

For professionals that require deep drawn parts and want a top service provider, Ming Xiao offers services for: mechanical engineering, medical-based projects, Electrnic Motor parts, Home and bathroom parts, and high grade supplier services for vehicles, such as high performance automobile engines.

Quality Assurance

Ming Xiao’s innovation and passion additionally utters itself in our incomparable customer service. The competitive prices of our Deep Drawn Parts allow our clients to get consistent profits and to keep our customers competitive in the market.

High Quality Material Usage

Thanks to superb management of the material micro fine abnormalities that happen in deep drawn parts, brittle hazards can be prevented assuring less stringent verification rate for every part.

Last but not least, continual research and development for the use computerised numerical systems such as CAD/CAM technologies, Ming Xiao puts quality before quantity, reliably completing exact orders for cutomers needs reliably and cost and time effectively.

The Right Choice For Deep Drawn Parts Manufacturing

In conclusion, Ming Xiao satisfies customers easily with any requirements for Deep Mould Part solutions and applications. Therefore Ming Xiao Mfg is the right choice when it comes to deep drawn parts and should be the pick for any major indutry requiring competitive prices, top-notch professionlisnm, efficient procedures, genuine material usage, and continuous customer service within their designated business operations.

We are professional Metal Stamping & Deep Drawing service provider from China, we have full experiences on custom produce Deep drawn parts for our oversea customers, If you have products which made by deep drawing process, pls feel free contact with us.

The technics & capabilities: Punching, cutting, deep drawing,bending / flexing / curving, pressing, forming,welding / bonding, riveting, grinding edge, lettering, components Assembly.

Available Materials for deep drawn parts: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc.

Finish treating: Anodizing,hard anodizing,electroplating of chrome/zinc/nickel plated, tinning,copperize,Colour spray-painting, blackening, hot-dip galvanizing, tephlon plating, etc.

Lead time for samples of deep drawn parts is about 35days.

Lead time for mass production: generally a order is 30-60days, if machining process is too complicated or quantity is very high,the lead time will longer.

We can provide COC (material certificate), Test Report, ROHS / SGS, plating report or coating reports also available !