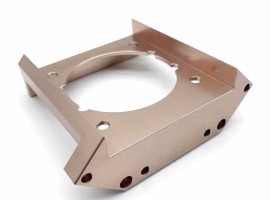

High-Strength Aluminum Forged Parts for Critical Applications

Our aluminum forged parts deliver exceptional strength, reliability, and performance for the most demanding industrial applications. Using advanced forging technology, we manufacture components with superior structural integrity that outperform parts made by other methods.

Manufacturing Process of Aluminum Forged Parts

The aluminum forging process involves several precise steps to ensure optimal quality and performance:

1. Material Selection

We start with high-quality aluminum billets of specific alloys tailored to your application requirements.

2. Heating

Billets are heated to precise temperatures (typically 350-500°C) in controlled furnaces to achieve optimal forging condition.

3. Forging Operation

The heated aluminum is shaped using high-pressure forging presses. We specialize in both open-die and closed-die forging methods to create parts with exceptional grain structure and mechanical properties.

4. Trimming

Excess material (flash) is removed from the forged component.

5. Heat Treatment

Parts undergo thermal processing to enhance mechanical properties including tensile strength and hardness.

6. Secondary Operations

We provide complete finishing services including machining, surface treatment, and quality inspection.

Key Differences: Forging vs Die Casting

Understanding the fundamental differences between forging and die casting helps in selecting the right manufacturing method:

Forging Process

- Solid state metal forming

- Superior mechanical properties

- Enhanced grain structure flow

- Excellent impact toughness

- High strength-to-weight ratio

- Minimal porosity defects

- Better fatigue resistance

- Suitable for critical applications

Die Casting Process

- Liquid metal injection

- Higher production rates for complex shapes

- Potential for porosity issues

- Lower mechanical properties

- Cost-effective for high volumes

- Suitable for less critical applications

Aluminum Material Types for Forging

We work with various aluminum alloys to meet different application needs:

- 6061 Aluminum: Excellent all-purpose alloy with good strength, corrosion resistance, and weldability

- 2024 Aluminum: High strength-to-weight ratio, ideal for aerospace applications

- 7075 Aluminum: Ultra-high strength alloy, comparable to many steels

- 5052 Aluminum: Superior corrosion resistance, perfect for marine environments

- 6082 Aluminum: Good mechanical properties and corrosion resistance

- 1050 Aluminum: Easy for cold squeeze pressing, can make thin wall aluminum shells, hollow core components.

Industry Applications

Our aluminum forged parts serve multiple industries with reliable performance:

Automotive Industry

- Suspension components

- Steering knuckles

- Wheel hubs

- Connecting rods

- Transmission parts

Aerospace Industry

- Aircraft structural components

- Landing gear parts

- Engine mounts

- Wing fittings

- Control system components

Industrial Machinery

- Hydraulic components

- Gear blanks

- Valve bodies

- Machinery frames

- Equipment handles

Defense and Military

- Weapon systems

- Armor components

- Vehicle parts

- Military hardware

Why Choose Our Aluminum Forged Parts?

- Superior strength and durability

- Excellent fatigue resistance

- Reliable performance under stress

- Cost-effective solutions

- Quality guaranteed

- Custom manufacturing available

- Technical support provided

- On-time delivery

Request a Quote

Contact us today for custom aluminum forged parts solutions. Our engineering team is ready to assist with your specific requirements and provide competitive pricing.

Phone: +86 137 80014913

Email: [email protected]