Ming Xiao Mfg Machined Plastic Parts

The materials used in precision workpieces made in CNC machining plants are divided into two categories: metals and engineering plastics. Metals include aluminum alloy, steel, copper, various hard alloys, etc.; besides metal materials, common materials in CNC machining plants are engineering plastics, which have irreplaceable insulation properties of metal.

Engineering plastics refer to plastics that can be used in mechanical equipment and engineering structures. They have metal-like properties and have high strength, stiffness and toughness.

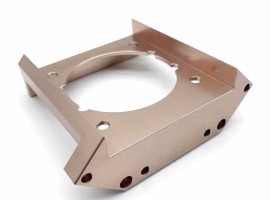

When it comes to precision machined parts made with a variety of plastics, Ming Xiao Mfg is the preferred supplier for businesses across the world. Our engineers have the necessary expertise to create exceptional machined plastic parts using CNC Milling and Turning processes to create plastic parts with stringent and exacting requirements.

CNC Machining for Quality Plastic Parts

Using CNC Milling and CNC Turning, our engineers are able to produce quality machined plastic parts that meet your highest standards. Our plastic materials include:

Common Used Engineering Plastics

| Name | Characters | Types of Fittings | Applications |

|---|---|---|---|

| POM | Excellent wear resistance, low friction, hardness, rigidity, and good dimensional stability | Ball, flange, and threaded fittings | Automotive industry components (shaft housings, gears, door handles, etc.), electrical and computer components, home appliances, and medical devices. |

| ABS | High Impact Strength, high rigidity, and dimensional stability | Pipe, flange, and threaded fittings | Construction materials, protective helmets, medical devices, electrical enclosures, automotive components, toys, and home appliances. |

| PA | High mechanical strength, rigidity, and toughness | Flange and threaded fittings | Wear resistant frames for machinery and automotive components, chemical tanks, and medical implants. |

| PVC | High impact strength, low cost, and high corrosion resistance | Pipe, flange, and threaded fittings | Protective covers, pipe and tubing, conveyor belts, electrical components, and biomedical products. |

| PC | Low weight, high chemical resistance, and high rigidity | Pipe, flange, and threaded fittings | Electrical components, protective housings, and medical implants. |

| PTFE | Low-friction coefficient, high temperature resistant, and widely used in robotics | Flange and threaded fittings | Insulators, gaskets, seals, lubricants, and corrosion resistant coatings. |

| EP | High rigidity, toughness, creep resistance, and good electrical insulation characteristics | Pipe, flange, and threaded fittings | Insulating components in electrical motors, pumps, and housings. |

| PU | Good flexibility, resilience, and chemical resistance. | Pipe, flange, and threaded fittings | Cushioning and shock absorption in a wide array of industries. Additionally, PU is used in headgear, and biomedical components. |

CNC Machining Equipment

As part of our commitment to top quality machined parts, we use only the most modern and advanced CNC machining equipment. Our horizontal, vertical, and high-speed CNC machines provide us with the capability to manufacture components with extremely tight tolerances in various shapes and sizes.

Our CNC Machining Capabilities

Milling Plastic Parts

Ming Xiao Mfg can mill plastic parts from a variety of plastics. Our engineers are able to create complex geometries with tight tolerances and superior surface finishes. We are experienced in producing parts with precise angles, complex curves, as well as the more straightforward parts.

Turning Plastic Parts

We use CNC turning to create precise components of different shapes, such as rods and tubes, for use in various industries. Our CNC turning machines make it possible to get very tight tolerances and the production of production-scale components.

Materials

By utilizing modern CNC machines, we can turn and mill plastics materials such as PEEK, POM, ABS, PA, PVC, PC, PTFE, EP, and PU. We are confident that we can produce components with superior quality in a short turnaround time.

Quality Control Process

We have very stringent quality control processes in our internal production and quality checks. We adhere to stringent quality standards by inspecting materials for any kind of defects or inconsistencies that may occur during manufacturing.

Choose Ming Xiao Mfg for your machined plastic parts?

When it comes to machined plastic parts, Ming Xiao Mfg is your go-to source for quality and reliability. Our engineers specialize in creating top-notch precision parts using the latest CNC Milling and Turning technology.

We use high-grade materials and have stringent quality control processes in place, so you can be sure that you will receive quality plastic parts from us. Contact us today to learn more about our Machined Plastic Parts solutions.

Watch more videos of our machining service, plz visit our Youtube Channel.